Small-scale thermal power generation

Suggestion of the small output of POWERTEK ENGINEERING.

Our engineering systems are as follows

The basic engineering & design are performed by technical engineer in charge confirms a request matter of customer.

A technical examination document and the drawing making share it with Japan by contents in Indonesia and explain it.

I ask the field about various consulting basically and do the explanation of confirmation and the result of contents.

※ We carry it out in Japan or Indonesia if it can be specified about the place.

※ We dispatch an expert as needed and illustrate by Japanese.

When we are assigned to local construction, and we dispatch an interpreter as needed, and it is said by the support of the customer instructor our instructor and

We do construction management. An instructor, the interpreter dispatches you and we dispatch an instructor as needed

from Japan and support it.

In addition, the present invention is not limited to Indonesia, also we will correspond for the provision of engineering in Southeast

Asia in general.

〈 Fluidized Bed Combustion Coal Boiler 〉

For steam generation and in-house power generation

Circulated Fluidized Bed Combustion Coal Boiler

( for steam generation and power generation )Fluidized Bed Boiler for steam and power generation,

using coal which is of low cost energy sourse.

Features

① The boiler operates with high stability and at a high efficiency of 85 to 90%.

② A broad range of choices in solid fuels is available since even powdered coal is efficiently burned.

( wood chips and sawdust can also be used as fuels. )

③ It is possible to perform a simplified desulfurization process by adding lime

as a measure to reduce SOx.

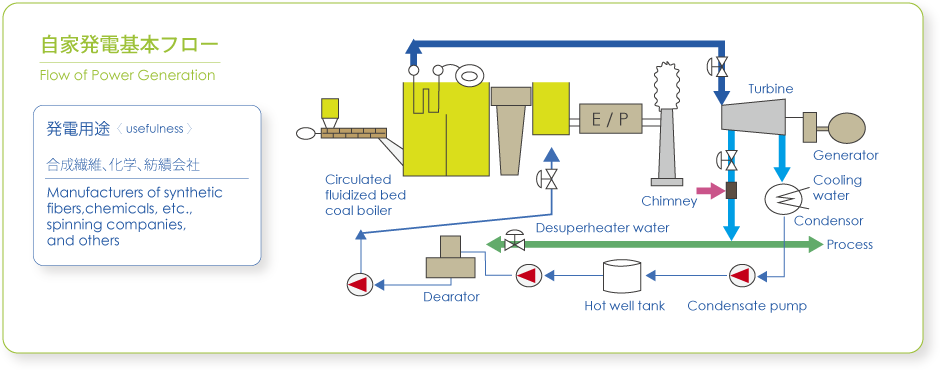

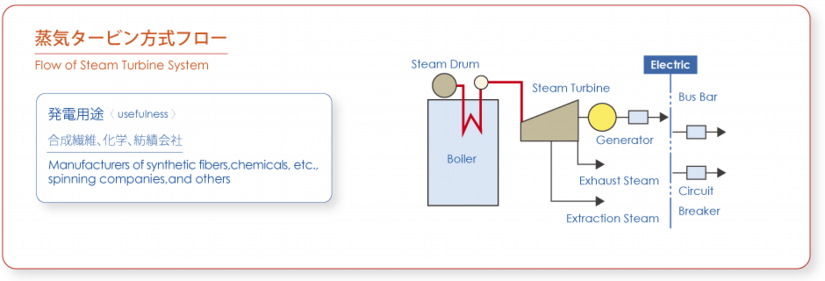

〈 Co-Generation Power Plant 〉

Co-Generation Power Plant

A highly efficient power / steam generation system for factory use, coordinated

with our engineering ability based on a lot of references. We propose the most

reasonable system from various fuel type to contribute to cost reducing.

Features

① A wide choice of prime mover options : BTG system, GTG system, D/E system, etc.

② A variety of fuels : natural gas, fuel oil, coal, etc.

③ A cogeneration is a cost-efficient solution ideal for a plant that uses both electricity and steam.

④ Energy cost reduction : 12 to15% more.