CO-GENERATION SYSTEM PRESENTATION

Jan. 2008

TEIJIN ENGINEERING LTD.

ENVIRONMENT ENGINEERING DEPT.

< VISION OF ENERGY SOURCE >

◆Saving of energy cost

◆Maintain stabilized power source

◆Diversification of energy source

◆Anxiety of Electricity supply

<<Capacity, Stability, Cost performance>>

----------------------------------------------------------

< CO-Generation system >

◆Purpose: Cost down of energy

◆Get stabilized electricity CFBC Coal Fired Boiler

+Steam Turbine + Generator

◆System: *We will design suitable system

----------------------------------------------------------

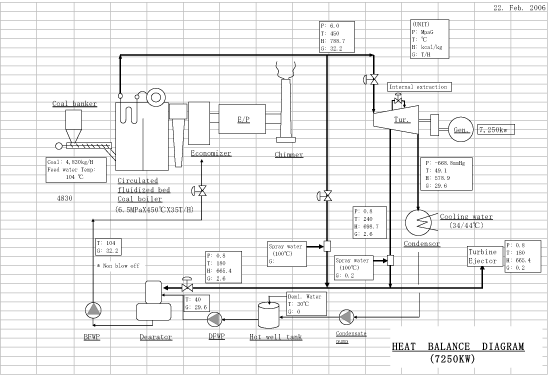

Site Conditions (Example)

◆Present:Steam consumption

・Steam consumption: 0 T/H

・Receiving : (Ave.) 6,250 kw

◆Future: Steam consumption for process

・Steam consumption: 0 T/H

・Turbine extraction steam: 2.7 T/H

・Receiving : 0 kw

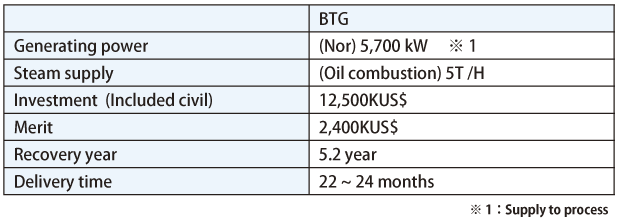

・BTG 7,250 kw

◆Specification of new plant:

・BTG Generating 7,500 kw

・Fuel Coal (Indonesia)

◆System: Boiler+Extraction & Condensate turbine

---------------------------------------------------------------------------------

Design Criteria of power plant

◆Protection system for Parallel operation with Commercial power

source & Generator

(Selective trip load system & Short circuit braking capacity)

◆Trip-off protection of power plant

◆Environmental issues:Particle, NOx, SOx, Noise, Waste water

---------------------------------------------------------------------------------

Design Criteria of steam boiler

◆Type: Circulated Fluidazed Bed Conbustion

*China has the advanced technology.

◆Fuel: Various kind of coals and biomass fuels can be used

◆Easy operation

◆Maintenance by WASA MITRA Eng. & Others

◆Environmental issues:

Particle: Electro Static Precipitator (Target: 50mg/Nm3)

NOx: Low NOx Operation (Low combustion temp. )

(Target: 300mg/Nm3)

SOx: Internal De-sulfurization (up to 90%)

Noise: Protection by housing or equivalent

Waste water: according to local regulation (Customer’s scope)

---------------------------------------------------------------------------------

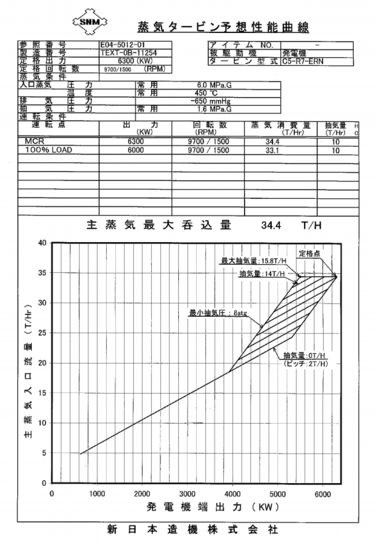

Design Criteria of steam turbine

◆Operation Hours: Continuous 8000 hrs/year

◆Easy operation: Digital governor control system, Auto start stop

◆Reliability: Steam turbine & Generator (Japan)

◆Maintenance Services:

① Turbine: Japanese S/V, Maintenance company in Jakarta

② Maintenance:

・Regular maintenance: Once per year

・Major maintenance: Once per 3-5 years

---------------------------------------------------------------------------------

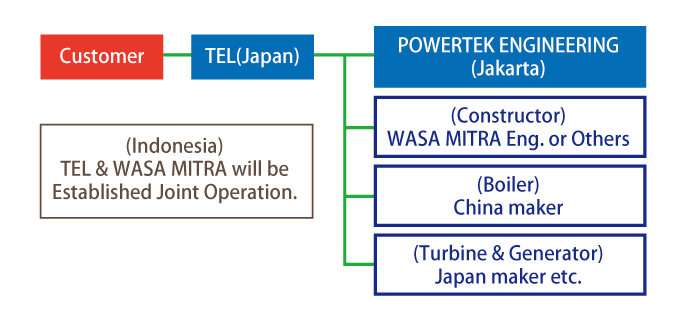

Formation of Project

◆Turbine performance chart

○Method of Extraction press. : Internal valve control

○Method of Exhaust press. : Governor valve control

---------------------------------------------------------------------------------

Conclusion

◆Strength of Teijin Engineering Ltd.

①Consistent management:

Engineering -- Procurement -- Construction -- Commissioning

②Present of know how for operation and maintenance

③Design based on User’s experience

We design & supply easy to use facility based on user’s needs.